OVERVIEW

This exercise uses an engine hoist, an engine block, and an aluminum “dog bone” to measure the weight of the engine block. The dog bone has strain gages attached. With the measured strain, students calculate the associated weight.

PRINCIPLES

Reinforces the relationship between strain and stress; and between stress and force. This exercise also provides opportunity for students to be exposed to several other important concepts: calibration of instruments, tolerance in machining, and variability in material properties.

WHAT YOU NEED

- Engine hoist (we used a Strongway 2-Ton Hydraulic Engine Hoist)

- Engine block

- Load leveler (to connect to engine block; we used the one that was included with the engine hoist)

- Strain indicator box (we used a Vishay P-3500)

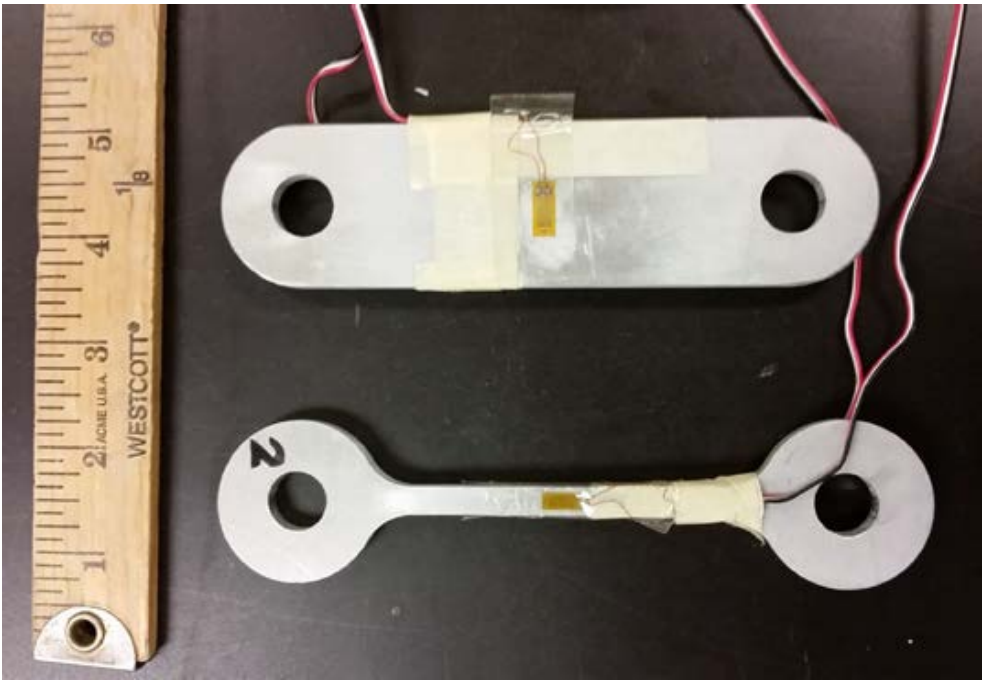

- An aluminum dog-bone with longitudinal strain gages attached on two opposite sides (we used 6061-T6 machined from 0.25-in x 2-in flat stock; ends were machined to accept the bolts used with the load leveler and the through was machined to 0.25-in x 0.25-in). See Figure 2.

- A temperature correcting aluminium piece with two strain gages attached (this should be machined from the same aluminum stock as the dog-bone but the dimensions are unimportant). See FIgure 2.

- 100-lb weight (to calibrate the “load cell” created by the dog-bone and strain indicator box)

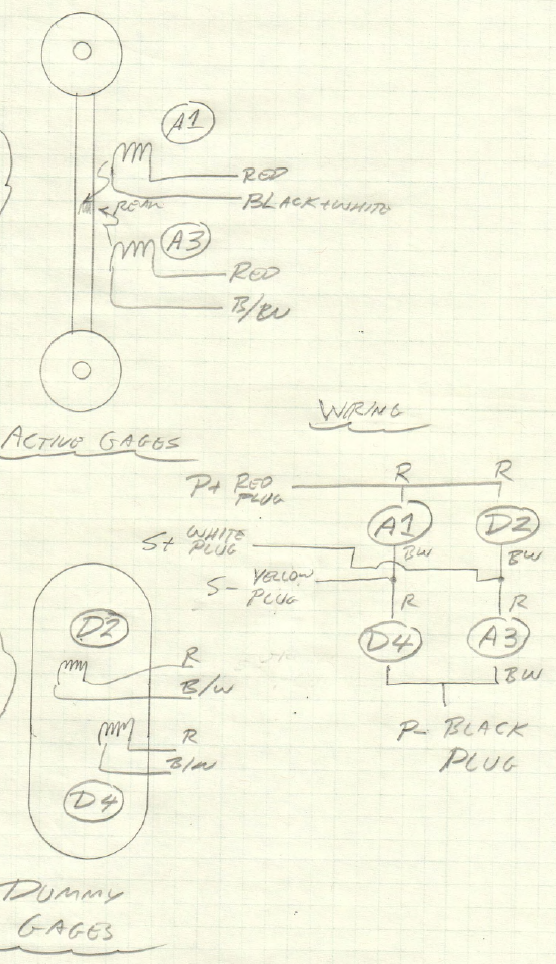

- The four gages from the aluminum pieces must be connected to the indicator box in a full-bridge configuration as shown in Figure 3.

HOW IT’S DONE

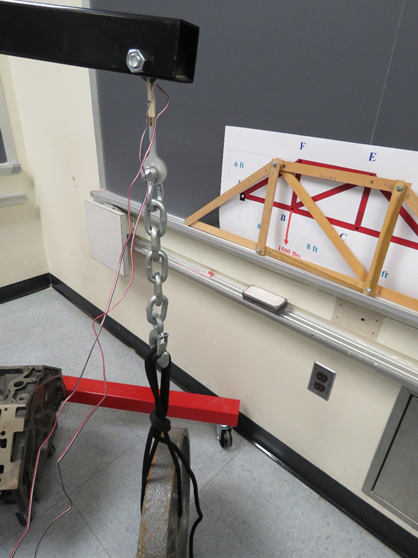

- Ensure the “load cell” functions prior to class starting. The “load cell” consists of the dog-bone, temperature-correcting piece, and strain indicator box all connected and powered up and zeroed.

- With the “load cell” connected to the end of the engine hoist, ask students to estimate what strain will be measured when a 100-lb weight is suspended. This should prompt recall of Hooke’s Law. This should in turn spark questions about what type of material and dimensions of the dog-bone.

- With a calculated prediction of strain for the 100-lb weight, suspend the weight and measure the strain. See Figure 4 for a better view of the connection of the hoist arm to the dog-bone to the chain and suspended weight.

- The measured strain will undoubtedly differ slightly from the calculated value which was made using a tabulated modulus of elasticity for the material. This can spark a valuable discussion about variability in measured material properties. Depending on how students were provided the dimensions of the dog-bone, this could also spark discussion about the precision of measurements.

- Remove the 100-lb weight … while discussing the importance of calibrating any instrument used for measurement.

- Using the calculated modulus of elasticity from Step 2 (or simply knowing the strain associated with 100-lb), hoist the engine block and use the measured strain to calculate the weight of the engine block. If you have previously used scales under the four hoist casters as described in this activity, you could compare the measured weight from measured to strain that that found using four scales. Ask the students which they trust more and why? This should lead to a discussion about the precision of different instruments.

REFERENCES

For more about this exercise and the principles the authors used to develop it, please see this paper.

For more about a refit of the statics and mechanics of materials course in which this exercise was developed, please see this paper.