Model Description

This is a simple demonstration of the basic principles and behavior underlying stress concentrations. Stresses at points of load application can be much larger than the average stress in a member. The same is true when a member contains a discontinuity. Paper members with the same mid-span width are used to demonstrate the stress concentrations that can occur at load points as well as at discontinuities: holes and fillets. This demonstration should take 8-10 minutes.

Engineering Principle

The stress concentration factor (K) is defined for a particular cross-section as

the maximum stress over the average stress. The maximum stress typically occurs near a discontinuity. The experimental results obtained for K are independent of the size of the member and the material used; they depend only upon the ratios of the geometric parameters involved (i.e., diameter of the circle, radius of fillet, or remaining width of cross-section).

What You Need

| Item | Quantity | Description/Clarification |

|---|---|---|

| Sheet of paper members | 2 sheets per student | Cut out the shapes. Two sheets/shapes per student. There are four shapes. Shape 3 has three (multiple) different configurations. Get some help if you have a big class. |

| Scissors | 1 | It important not to create stress concentrations when cutting out the members (i.e., do not create notches when cutting out the shapes), especially the third member with the square corners. |

| Single hole punch | 1 | Used to put the hole in Member 2. |

How It’s Done

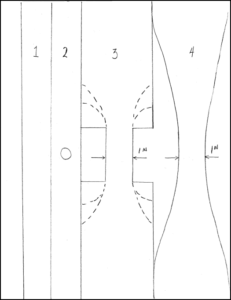

Before Class: Cut out the members so that each student has at least one of each of the four paper member configurations (figure below). Note that the cross section at the middle of each member is the same (in this case 1 inch). Member 3 has three configurations – no fillet, a circular fillet and a larger/possible non-circular fillet. You decide if they have one of each – the reason for two sheets of members – per student. Also many students will place impact loads on the members, so they will need replacement members when this occurs.

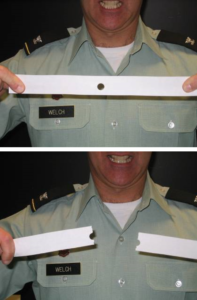

In Class: Have the students make a prediction as to which member will break with the least to most load. After the presentation of the theory, calculate the max stress each member will experience based on an assumed applied load. The students then reorder their predictions and statically load their specimens 1 thru 4 (specimen 3a (with no fillet, just a notch cut), specimen 3b with one of the two fillets) by only using their thumb and index finger. We could use a clamp and a spring load for accuracy, but that is not really necessary. After hand loading the first member, some students apply a pinching action at their load points that causes a stress concentration and pre-mature failure at the finger locations. Others will apply the load as an impact load. Each loading situation provides key discussion points for the effect of the load on the experiment (and the reason for having more than one member type per student). Emphasize the need to not create a stress concentration at the finger point. It is important that each student has a Member 3 that has no fillet, just the notched out section.

Observations: Some students will not be able to break Members 1 and 4 at the center without an impact load (moving fingers towards each other, then applying a tension load rapidly) or at the load point with a pinching effect. The students should observe that a gradual change in shape will allow for a smaller stress concentration factor – less of a stress concentration effect (i.e., the stress concentration factor is reduced as the radius of curvature of the fillet is increased). They should also see that no fillet is a very dangerous situation and creates a very large stress concentration at the corner.

Additional Application: Some students will not be able to break Members 1 and 4 at the center without an impact load or at the load point with a pinching effect. Highlight the strength that some materials possess in tension when we see very little strength in compression. This spurs a deeper discussion back into the reason we are studying mechanics of materials or the strengths and behaviors of materials. The proper selection of the proper material leads to efficiency and cost effectiveness. It is also humbling to see some of the stronger students not be able to break a simple piece of paper…